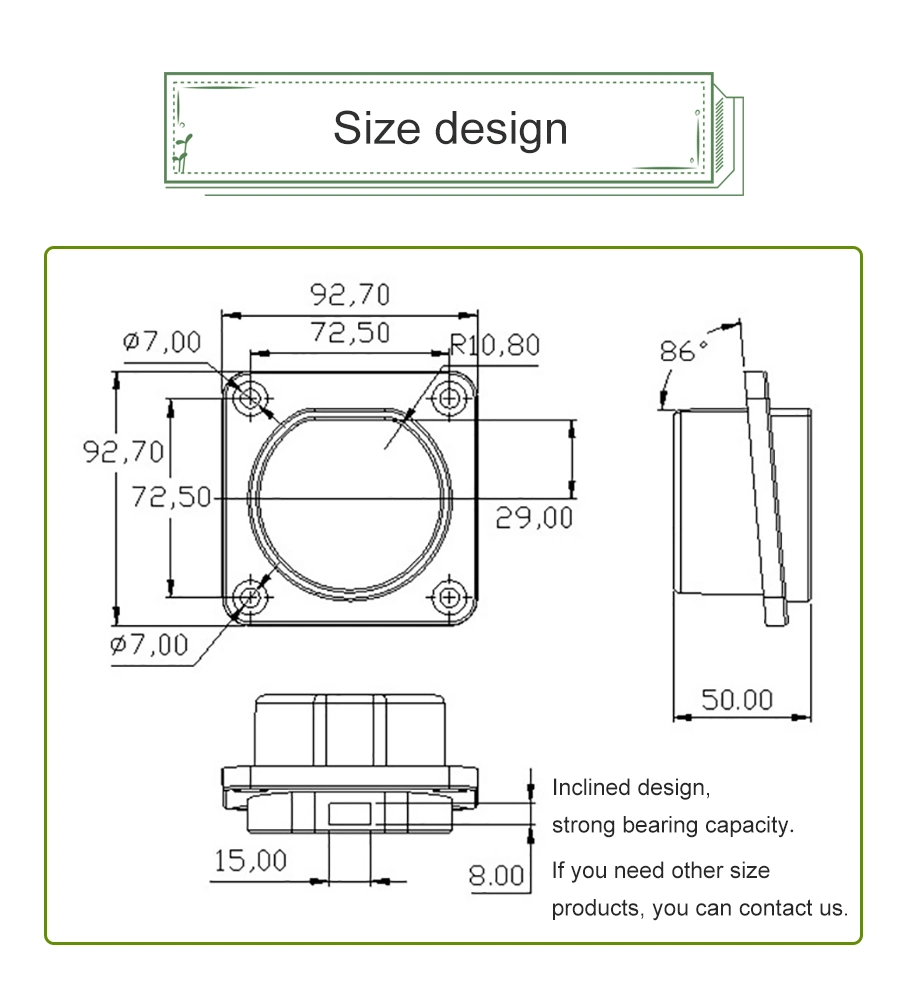

EV Ultra Charging Holder Holster Dock Connector Electric Vehicle Charger Plug Hanger

Basic Info

| Model NO. | JF-hg |

| Export Markets | Global |

| Shipping Port | Qingdao |

| Place of Origin | China |

| Transport | by Sea or Air |

| Packing | Wooden Cases or Carton |

| Surface Treatment | Spraying/Polishing/Galvanized/Electroplating |

| Weight | Customized |

| Sample | 7 Days Ready |

| Processing | as Per Your Drawing |

| Materials | as Per Request |

| After-Sale Service | Definetly |

| Certificate of Origin | as Per Request |

| Transport Package | Plywood Box |

| Specification | As your requirement |

| Trademark | OEM |

| Origin | Weifang City, Shandong Province, China |

| HS Code | 7326199000 |

| Production Capacity | 50000PCS/Month |

Product Description

EV Ultra Charging Holder Holster Dock Connector Electric Vehicle Charger Plug Hanger

Strict inspection we do during operationExperienced QC testers to check the products dimension, surface and performance according to drawings specification.Experienced IQC to check the dimensions and surface of the incoming material.Experienced PQC to inspect full-course during the processing.Experienced FQC to inspect all the plating products from outsides and make the 100% inspection before the shipments. Quality sample will be provided for your testing before production according to ISO 9001: 2015.We are pleased to service you with excellent quality, reasonable cost and grow with you together.

| Item | Description |

| 1.Mould material | P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 |

| 2.Hardness of steel | vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 |

| 3.Inserts / Slider steel | H13 (DIN.1.2344),tempered with HRC46-50 |

| 4.Mould spare parts | H13 (Din 1.2344),tempered with HRC40-45,nitrited with HRC60-62 |

| 5.Mould base | LKM,HASCO |

| 6.Mould cavity | Single / Multi |

| 7.Runner system | Hot / Cold |

| 8.CAD centre for data formats | IGES,X_T,STP & DWG,etc |

| 9.Plastic material | ABS,PC,PE,PP,PS. |

| 10.Mould life | 80000- more than 1000000 |

| 11.Delivery time | 4-8 weeks |

| 12.Terms of payment | T/T, Paypal, Western Union and so on |

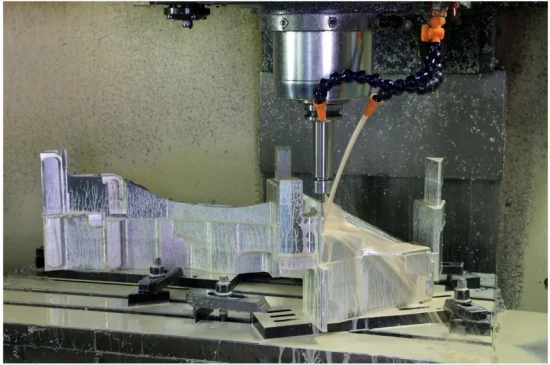

From CAD to Low, Medium, and High-volume production runs. Custom molded rubber and plastic product contract manufacturing service. Rubber and Plastic parts are available in a variety of materials, hardness, and colors to match customer's specific applications. Molded rubber and plastic products such as plastic parts, rubber gaskets, joint, seals, grommets, compression seals, washers, grips, diaphragms, expansion joints, couplings, stopping seal elements, valve parts, rubber pulley lagging, rubber isolator parts, rubber wear pads, nozzle liners, cow and horse mats, flooring mats and rubber dog toys can be fabricated. Materials such as Buna-N, Buna-S, nitrile, butyl, natural rubber, neoprene, silicone, EPDM, SBR are used. Capabilities also include fast reverse engineering, prototyping, compression molding, injection molding, extrusion, and assembling. Advantages: 1. Competitive price. 2. Strict quality control system. 3. Quick mold making and delivery. 4. Advanced equipment, excellent R&D teams. 5. Professional technicians and rich experienced workers.

Q1. What's your main business? A1: We are mainly making plastic injection moulding parts. Q2. Are you a trading company or manufacturer? A2: We are a manufacturer with foreign trade experience. Q3. What types of files(drawings) do you accept? A3: With our cad systems we can take the following files in:.STP / .IGS / .DXF / .DWG / .PPT / .STL / .X_T / .CATIA /UG files, etc.. Q4. Can you Provide OEM? A4: Yes,we can provide OEM service. Q5. If make the molds for us,will you disclose our files? A5: All the files are confidential, we can sign the NDA first when required. Q6. Do you provide design service? I have an idea for a new products,but I don't know whether it can be realized. Can you help? A6: Definitely ok. Our R&D department will help you design the idea to be realized with extensive technical supports. Q7. Do you have after-sales service? A7: Yes,we will provide technical supports with 7x24 hours. Q8. If I decide to go ahead with my project,how long will it take to get the trial samples? A8: 3-6 weeks depends on the part construction. Q9. How about your facilities? A9: 8 sets sodick EDM, 9 mirror EDM, 8 high speed cnc.Quality First,Price Best,Service Foremost! We assure you of our best services at all times! If you are interested in any of our products, please send message to us through below approach!