OEM Manufacturing CNC Machining Machined Metal Steel Aluminum Automotive Hub Vehicle Ship Part Plate Mouting Bracket Electric Car Auto Machine Motor Spare Parts

Basic Info

| Model NO. | ZW052 |

| Business Type | Manufacturer |

| Quality | 100% Quality Inspected |

| Drawing | CAD / Pdf/ Dwg/ Igs/ Step/X-T etc. |

| Finish | Anodizing |

| Color | Customized |

| Delivery | 30 Days After Order Confirmed |

| Process | Forging, Machining,Testing, Packing |

| Tolerance | +/-0.01-0.05mm as Per Customers Drawing |

| Test Equipment | Measurement Instrument, Projector, CMM, Altimeter, |

| Logo Method | Laser Engraving, CNC Engraving, Screen Printing, |

| Package | Cartons or Wood Pallets, as Customer Requriement |

| QC Control | 100% Inspection on Critical Dimensions |

| Equipment | 3/4/5 Axis Center Machining/Milling/Lathe |

| Transport Package | Plywood Box |

| Origin | China |

| HS Code | 7616991090 |

| Production Capacity | 5000000 Pieces/Year |

Product Description

ABOUT US

YYZW Machinery was founded in 2012, which is located in the Ningbo City, Zhejiang Province. YYZW has 12000 square meters standard factory with 40 employees and our target is 100 employees.

Equiped with advanced, high efficiency and high standard Japan and Taiwan brand machines, including kinds of CNC milling machines and turning machines, lathe machines, milling machines, surface grinder, internal and plain grinder, WEDMLS, WEDMHS, etc. Relevant inspection equipment are also fully equipped. Parts with tolerance ups to ±0.002mm can be supported.

Professional in providing high precision turning and milling parts, rivets fasteners, and inserts for communication accessories, auto parts, sports equipment, lighting accessories, optical instruments, medical equipment, furniture parts, etc.

Product Description

| Products Name | Custom Made CNC Machined aluminum Parts Auto Parts | |||

| Material | Nylon66,HDPE,UHMW,POM,ABS,PP,PC ,PVC | |||

| Process | CNC Machined | |||

| Certification | ISO9001 | |||

| Color | Any color you required | |||

1, High Wear-resistance

2, Good Anti-corrosion resistance

3, Good self-lubrication

4, Very high-impact resistance

5, Very good electrical insulation

6, High inadhesion resistance

7, Non-toxic and clean property

Stamping workshop Mould workshop Machining workshop

CNC Machining workshop General turret milling machine 60T Bending Machine

Turning workshop Texting Lab 3D Mesure

Normally be packaged in brown box (customized color box packaging)

About Express

Quality and inspection:

Fegular checking on line from production in each workshop, one special inspector inspect the goods in random during the period time of production. we are able to provide you test certificate and mill certificate if required

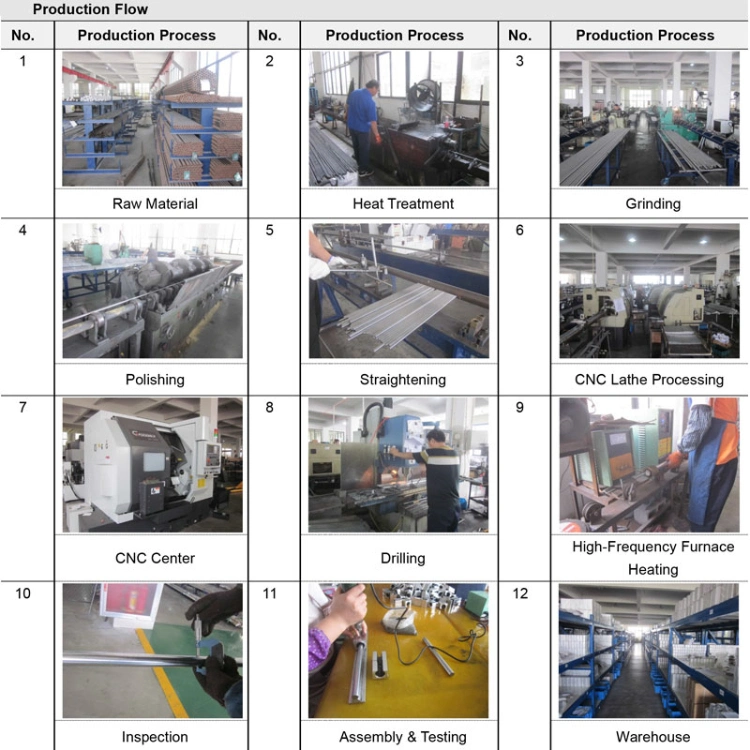

Production steps :

1) purchasing the material and forged the semi-products

2) processing the semi-products in workshop

3) assembling the goods

4) testing the sealing in pressure and checking quality of the goods

5) package

6) deliveing the goods on time

Brass Chemical Composition % (Mass Fraction) Symbol with * is DZR Brass

DZR/DR(Dezincification Resistant)Brass are recommended for use with drinking water distribution

Quality Assurance:

ISO9001: 2008 and ISO/TS16949: 2009 and GMC of TUV ( specially for auto industy) certification.

Machining Equipment:

Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes /Wire-cuts / Laser Cuts / CNC Shearing Machines / CNC Bending Machines / etc.

Materials:

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.Brass Alloy:3602 / 2604 / H59 / H62 / etc.Stainless Steel Alloy:303 / 304 / 316 / 412 / etc.Steel Alloy:Carbon Steel / Die Steel Q235 Q345 45# 35# 30CRMO 40CRMO 40CR/ etc.Other Special Materials:Lucite / Nylon / Bakelite / etc.We handle many other type of materials. Please contact us if your required material is not listed above.

Surface Treatment:

Blacking, polishing, anodize, chrome plating, zinc plating, nickel plating, tinting

Q&A

Q1: What's kinds of information you need for quote?

A1: Kindly please provide the 2D/3D drawings (PDF/DWG/DXF/IGS/STP/SLDPRT/etc) and advise material, finish, quantity for quoting.

Q2: What is your MOQ?

A2: MOQ depends on our client's needs, besides, we welcome trial order before mass-production.

Q3: What is the lead time?

A3: Depending on your specific project and quantity.

Q4: Available for customized design drawings?

A4: Yes, please send the technical drawings to us. It's better if you can send both 2D and 3D drawings ifyou have.

Q5: If the parts we purchase from your company are not good, what can we do?

A5: Please feel free to contact us after you got the products. Kindly send us some photos, we willfeedback to our engineers and QC departments and solve the problems ASAP.

Q6: Are you a manufacturer or trading company?

A6: We are a manufacturer, we are located in Ningbo, China.

Q7: Will my drawings be safe after sending to you?

A7: Yes, we will keep them well and not release to third party without your permission.